Harmful Mistakes You Might Be Making with Your Moisture Meter

Using a moisture meter removes so much guesswork and approximation from daily tasks. With accurate readings and reliable tools like the ones we...

Using a moisture meter removes so much guesswork and approximation from daily tasks. With accurate readings and reliable tools like the ones we...

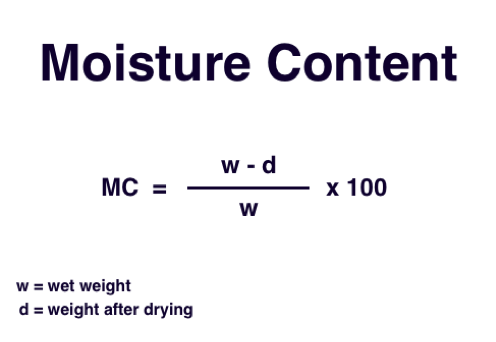

When it comes to food safety and quality, there are two critical measurements that all food manufacturers should take: moisture content and water...

Maintaining an acceptable moisture level is one of the most critical elements in successful grain storage. Anyone in the industry knows the...

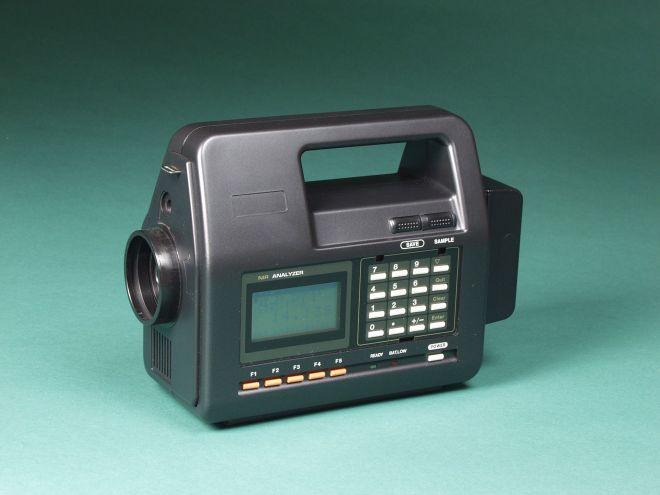

Kett has been in business for over 70 years. One of the keys to our company's longevity is actually the longevity of our instruments. Many Kett...

Paper manufacturing is a complex industry involving an even more complicated process. With speedy time demands, little margin for error, and the...

Investing in a quality, easy-to-use moisture meter can have a big impact on your business, but with seemingly countless options, choosing a moisture...

When you lease a Kett moisture meter, we can guarantee you’ll be cash-positive from day one. How?

If you’re like most business-minded professionals, you’ve probably asked yourself the following question: “How am I providing value to my customers?”

When it comes to designing packaging for fresh produce, the #1 goal of the packaging should be to maximize the freshness and longevity of the...

Though virtually unchanged since 1970, the familiar amber vials used by pharmacists for decades have recently fallen under scrutiny. In 2013, an...