Summer seems like the perfect time to get all kinds of construction projects done. The weather is warm, the sun is out and days are longer, allowing you more time to accomplish your tasks.

Summer seems like the perfect time to get all kinds of construction projects done. The weather is warm, the sun is out and days are longer, allowing you more time to accomplish your tasks.

However, if you’re not careful, summer weather really can affect the strength, durability and longevity of your concrete.

Here’s how the summer season can impact the fortitude of concrete—and what you can do to monitor and prevent this from happening.

Moisture, Humidity and the Strength of Your Concrete

Humidity doesn’t just make it feel hot and sticky or affect our ability to bake a great loaf of bread. It also really can play a role in the strength and lifespan of your concrete. This is true, whether you are making a concrete pad at your home or building a 20 story high-rise.

Studies have shown that at an early age, curing concrete isn’t all that affected by humidity, but as the curing process continues, the effects of higher humidity levels become increasingly pronounced, resulting in more common occurrences of fractures.

Here’s how humid summer weather can take a toll on your concrete:

Humidity and Compressive Strength

Rising summer temperatures and humid air can affect concrete as it cures and hardens over time. How does this happen? For starters, when the relative humidity levels start to soar, this affects the compressive strength of concrete. As humidity increases, the compressive strength of the concrete decreases, which can affect its durability and longevity.

Humidity and Concrete pH Levels

Additionally, there is a direct correlation between relative humidity levels and the pH levels of concrete. When relative humidity levels increase, so do the pH levels of concrete. How does this affect its strength? Higher pH levels actually can compromise the integrity of both the concrete itself as well as any adhesive or coating that’s attached to it.

Humidity and Microbial Growth in Concrete

Microbes and bacteria are everywhere, including in concrete. When additional moisture or humidity comes into play, it can create problems for concrete. Moisture, humidity and warm weather are the ideal conditions for mold and bacteria to grow and reproduce, which will affect the strength of concrete.

Mold growth within concrete can affect the wellbeing of individuals who live near the affected concrete, creating a major health risk.

How Summer Heat Can Affect Your Concrete

Just like humidity levels increased the risk of fractures and other structural issues, concrete also gradually can change from ductile to brittle when humidity levels decrease and the hydration time speeds up. This can easily happen when hot summer temperatures affect concrete’s evaporation time.

Concrete cures best between a range of 70 and 80 degrees Fahrenheit, so if temperatures rise above that threshold and climb towards 90 degrees Fahrenheit, your concrete can be affected and you can run into problems like these:

Surface Issues

Hot weather, wind and dry conditions can increase your concrete slab’s rate of evaporation, which can threaten the integrity of the top layer of concrete. Water quickly evaporates from the surface layer, which can cause the mix to be drier and therefore susceptible to surface cracking and shrinkage.

Reduced Strength

During the hydration portion of the curing process, water is absorbed and crystals form in the concrete. This needs to take place slowly over time. Cooler concrete takes more time to hydrate, which allows the crystals to form and grow in durability.

When the weather is too hot and too dry, the timeline for this process is shortened dramatically. The concrete mixture has less time to hydrate these forming crystals and create a strong compressive strength. This means that concrete curing in hot weather can suffer from limited strength and durability.

How a Concrete Moisture Meter Can Help

Moisture can do a great deal of damage to your concrete and its protective coatings. Because it is porous in nature, issues arise when water is trapped within the concrete. Concrete-water ratios can make a big difference in the permeability of concrete, but air humidity and summer heat also can affect the rate at which moisture migrates through drying concrete.

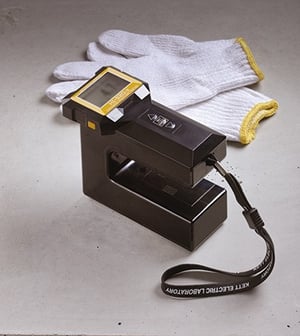

A moisture meter like the HI520-02 Concrete and Mortar Moisture Meter is essential to locate and measure moisture content in concrete.

Flooring installers can test concrete humidity as water passes through the concrete’s surface even after it hardens. This kind of testing is critical in indoor installations, where high levels of moisture and trapped water in concrete can create mold or lead to bubbling or degradation of the strength and integrity of the concrete. It can also cause mastic (used between flooring and the concrete slab) to fail.. or worse to partially fail, causing the flooring to be removed and a new floor re-installed.

This moisture meter comes with an assortment of factory calibrations to share fast, accurate moisture readings. It’s highly portable and even works when waterproofing, finishing and painting concrete, which makes it ideal for construction sites.

What does this mean for you as a contractor, homeowner, facilities manager or someone who pours concrete? Multiple moisture tests should be conducted throughout the summer to monitor concrete as it continues to dry, checking the levels to ensure a quality, long-lasting product that is strong and safe. Checks should be made in multiple locations, especially on larger sites as drying rates and curing rates may substantially differ.

The HI520-02 Concrete and Mortar Moisture Meter comes with eight custom programmable calibrations, which allow the user to calibrate for both deep and shallow samples. You can monitor whether or not the surface of your concrete is drying faster than the rest of the concrete thanks to the hot, dry weather.

Best of all? Even in summertime, the HI520-02 moisture meter adjusts for temperature, which means that you won’t get skewed results just because the concrete has been heated up by the blazing afternoon sun.

At Kett, we’re here to provide the instruments you need to ensure quality construction whether you’re working with concrete, drywall or wood any time of the year. From chilling winter temperatures to the dog days of summer, we can help keep you in successful operation year-round.

Want some help locating the perfect instruments in any season? We’re happy to help! Contact us today for more information!