Have you ever heard the saying, “you get what you pay for?” We’re sure rice farmers have. Because the purchasing price of their rice crop is directly correlated to the crop’s quality, rice farmers know that they must maximize their rice crop’s quality if they want to get the best price. And while it’s hard for rice farmers to avoid any quality issues caused by Mother Nature like droughts or flooding, one way that they can ensure their rice meets the highest possible quality standards is by using a rice whiteness tester to frequently analyze their rice’s quality.

Have you ever heard the saying, “you get what you pay for?” We’re sure rice farmers have. Because the purchasing price of their rice crop is directly correlated to the crop’s quality, rice farmers know that they must maximize their rice crop’s quality if they want to get the best price. And while it’s hard for rice farmers to avoid any quality issues caused by Mother Nature like droughts or flooding, one way that they can ensure their rice meets the highest possible quality standards is by using a rice whiteness tester to frequently analyze their rice’s quality.

Our C600 Instant Rice Whiteness Tester, for example, set the world standard for rice testing instruments by becoming the instrument of choice of the International Rice Research Institute (IRRI). With the help of these instruments, rice merchants can increase their profitability by providing an ongoing whiteness analysis of their milled grain to accurately assess its quality, which ensures a fair purchasing price of their rice while establishing classification standards for the global rice industry.

Rice Whiteness Testing Improves…

1. Quality

According to the IRRI, the physical quality of milled rice is characterized by a combination of desirable and measurable characteristics, such as moisture content, milling degree, chalkiness, damaged grains, and whiteness (among other things). Whiteness is often measured to determine the milling degree, which is a measurement of the percent of brown rice removed during the milling process. This influences the color of the rice, consumer acceptance, and cooking behavior, as undermilled rice does not cook as well. In order to make sure that your rice meets the proper milling requirements, the IRRI recommends using a rice whiteness testing instrument, such as the Kett C600, to obtain lab-quality whiteness values quickly, accurately, and without destroying the sample.

2. Grading

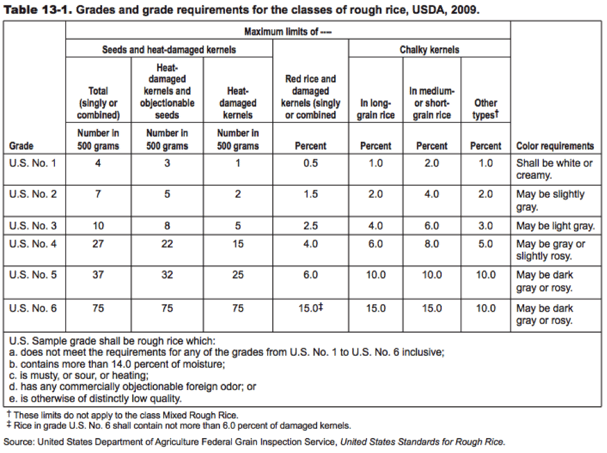

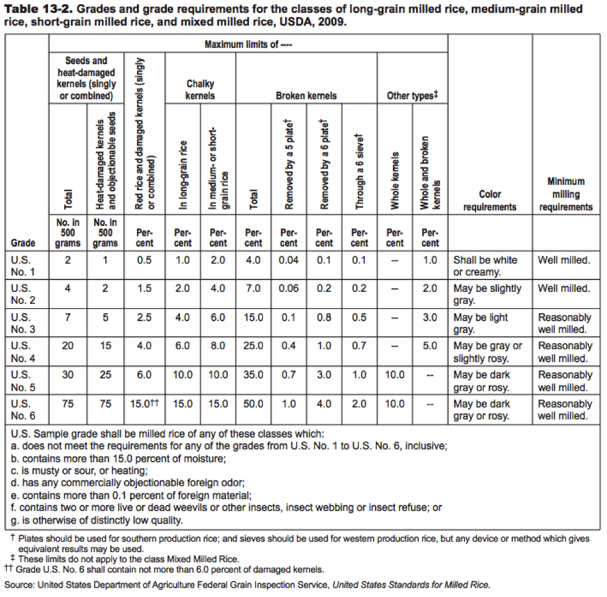

When it comes to determining the value and quality of rice, the whiteness of the product and proportion of broken grain are two of the biggest factors. In fact, the United States Department of Agriculture (USDA) has established rice grades for both rough and milled rice that help both buyers and farmers know the specific quality of their rice prior to the sale. In order for farmers to maximize their crop’s profit, a rice whiteness testing instrument can be used to ensure that their rice is at its optimal levels before harvest and milling. Our single kernel moisture tester, the PQ520 shows the moisture dispersion of a sample. When that dispersion narrows, it’s the optimal time to harvest the rice.

Because farmers still need to meet kernel quality standards in order to earn the highest grade, they can also use our TX200, RN300, and RN500 testing instruments to assess the grain quality of their rice kernels.

3. Profitability

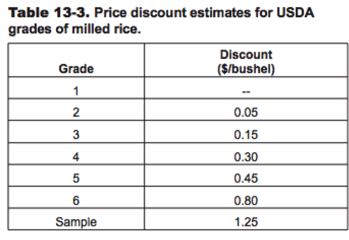

In addition to establishing quality grades for rice, the USDA has also listed price discount estimates for each grade of milled rice. Looking at the table below, for example, you can see exactly how rice’s grade classification can directly impact your profitability. In order to increase quality and maximize profits, it’s key to sell your rice at optimum prices each year, regardless of the yield and competition from overseas market. No matter what’s happening in the marketplace, it’s important to remember that a lower-grade crop will always command a lower price than a higher-grade product. Using a rice whiteness meter, grader, and moisture meter, merchants can accurately assess their rice’s quality and sell it at the highest possible price.

Want to learn more about how rice whiteness testing instruments can help maximize the profitability of your rice crop? Download our C600 Whiteness Tester brochure, or talk to one of our qualified engineers by clicking the button below.