Purchasing equipment is important to your business, but it can be a daunting task. This is especially true when the market is flooded with equipment from companies that you do not trust, that have disappointed you in the past, or have so many products that you are not sure where to begin.

Purchasing equipment is important to your business, but it can be a daunting task. This is especially true when the market is flooded with equipment from companies that you do not trust, that have disappointed you in the past, or have so many products that you are not sure where to begin.

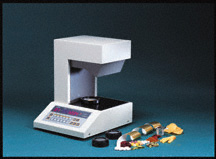

In chemical processing, food production, manufacturing, as well as packaging, one device that is commonly considered to have these problems is the purchasing of an NIR analyzer.

This device is crucial to quality and process control, yet, it can be difficult to ensure that you get a strong return on investment (ROI) for your purchase due to market demands and quality of instruments. The following explains more on what the NIR analyzer is, why you need it, and how you can better evaluate your options before purchasing.

NIR Analyzer – How it works

Near-infrared spectroscopy or NIR is a methodology that is important in product development and packaging. The importance of quality in such items as pharmaceuticals, chemical research, food production, and packaging cannot be disregarded. The goal of an NIR analyzer is to instantly measure moisture and/or organic composition without harming the product. As with any infrared light, some of the beam will be absorbed while the remainder will be reflected back. The ratio of absorbed light to reflected light serves as an indicator of the substances and chemicals contained within and provides a unique ability to ensure that the chemicals and concentrations are within specifications. The light is completely harmless to both the product and the user.

Anticipated Results

Evaluate your product’s quality before choosing an NIR Analyzer for your business. Purchasing this instrument is an investment, but one that your business needs. For this reason, you will want to ensure that you are getting a solid ROI before doing research about the instrument quality and the company qualifications first.

Determine which product characteristics you want to measure (moisture, fat/oil, protein, ash, coat weight, solvent/alcohol content, product id, etc.). Review your quality control logs to determine how often product has needed to be reworked or scrapped because it was out of specification. Now, put a dollar amount to the annual waste by multiplying this lost by the cost of the product (or the sales value if you are volume constrained). This becomes your initial annual payback goal.

Will it work on my product?

Next, rather than speaking with the sales agent or instrumentation manufacturers through which you are purchasing or considering purchasing (who will most likely provide you with a biased understanding of their product), do independent quality evaluations on what the device provides. Remember, the cheapest and the most expensive instrument provide no return on investment if they don’t work effectively on your specific product.

This can be done in several ways. To start, ask for recommendations from companies already using the product. These individuals can talk to you without a salesman bias. Further, you could go online and do your own research. Look for product and company reviews as well as quality control evaluations. Look for any recalls or any problems that you see recurring in customer complaints. Most instrument manufacturers will have a few “chosen” referral customers. These may not be in your industry, and even if they are, they may not be able to tell you specifics due to confidentiality. Even with great reviews, it doesn’t mean the product will work on your application or in your location.

Instead, invest in a company that has their own checks and balances system, it shows that they care about their products as well as their clients. They don’t “oversell” the product and they take the time to understand your measurement requirements. This helps ensure that the solution they provide will work on your product in your current environment. Companies that have a written performance guarantee which claim you will get what you need from the instrument or you don’t have to pay, tend to be trustworthy. Some instrument companies even let you rent a trial instrument with no obligation to purchase. You may wish to consider a supplier that will accept some of your samples for a preliminary calibration. However, remember, this is only preliminary and a better test of actual performance will occur when you have the instrument at your facility and are able to use your referee method to generate a wide array of comparison samples for calibration and testing.

Type

Make sure you get the right NIR analyzer for your needs. There is not a “one size fits all” with regards to infrared instruments. There are certain processes and internal mechanics that work best when analyzing specific types of products. Even if the instrument has great specifications, if it won’t work effectively in the location or with the staff members you want to utilize,your company will not see an effective profit from upgrading to an NIR analyzer.As an example, it would be better to have a portable system rather than a desktop system if your product changes quickly and you have multiple locations within your facility that you wish to evaluate. When considering online systems, look at the environment where it will be mounted and see if the instrument needs to have an air purge, cooling system, or external housing to guarantee it provides an extended life. When looking at a desktop instrument for use in a “non-lab” environment, wouldn’t it be nice if the system automatically measured without having to touch the system... thereby keeping the instrument as clean as possible?

Financing

Does the supplier offer financing?. Many times, this can help you get the internal support you need to move the project forward. It’s a lot easier to justify $10-20 per business day instead of $15,000-$30,000 in out of pocket capital. Talk with your supplier and see if they can help you here with inhouse or third-party financing.

Summary

To ensure you get the best ROI possible, make sure that the instrument you are buying is the one that is right for your needs. Discuss with the manufacturer the number of products that can be analyzed, look to the capabilities of the machine, ask for guarantees, and feel free to ask questions and raise your concerns. The NIR analyzer should work for you, and not you for it.