Last year, a feed mill in Weimar, Texas, caught fire thanks to one small spark from an overheated bearing in the elevator leg of the mill. This led to a dust explosion and a resulting fireball that echoed through the feed mill with a cannon-line sound and could even be heard several miles away.

Last year, a feed mill in Weimar, Texas, caught fire thanks to one small spark from an overheated bearing in the elevator leg of the mill. This led to a dust explosion and a resulting fireball that echoed through the feed mill with a cannon-line sound and could even be heard several miles away.

It’s a cautionary tale for anyone handling crops, feed, or anything else that requires heating and drying before storage.

Fortunately, in the case of this incident, firefighters were able to douse the ongoing fire, and the situation was handled without injury or any major damage.

But not every scenario like this ends without bodily harm. The other problem? These kinds of fires lead to a loss of sellable crops, which creates a financial hit that will be hard to recover from.

The Right Moisture Levels: A Delicate Balance

Preparing crops for storage can be a tricky thing. Too moist, and stored crops can quickly spoil, rendering that entire portion of the harvest unsellable, leading to a major loss of income. Too dry, and sellers not only risk missing out on profits when crops are sold by weight, but they also increase the risk of fire.

For example, wet corn can be stored for a brief period but needs constant monitoring and really is only meant as a stop-gap while harvesters wait for a drying backlog to clear. During this time, the bin needs regular aeration, and those managing the situation need to look for trouble signs, that includes:

- Hot spots

- Visual spoilage

- Foul odors

- Other signs of spoilage

This wet corn needs to be stored at the lowest possible temperature to keep microbial growth at bay. Conversely, growers and handlers of crops need to be just as careful not to "overdry" their harvests.

Especially during wet harvest seasons, farmers don’t have much choice besides sending their harvested crops through a grain dryer. Leaving the crops unharvested in the field can lead to an increase in field losses, which can quickly climb to substantial amounts. According to Feed Navigator, harvesting crops in November can create field losses between 3% and 5%. But leave the crops unharvested until December, and these field losses increase to a crippling 22% thanks to weather-related issues, disease pressure, and wildlife damage.

So farmers who need to store their crops are left with one option: grain dryers. However, these can pose a risk of fire.

Grain Dryers and the Increasing Risk of Fire

Fires happen in grain dryers all too often, and the resulting damage can be extensive. When waiting for crops to fully dry, monitoring ongoing changes in moisture levels is key to prevent overdrying — and the increased potential for fire. Especially when drying high-moisture corn, outside screens can quickly accumulate debris, boosting the risk of fire.

According to Successful Farming, any dryer that uses an open flame poses a constant risk of fire. Operators can reduce this risk by cleaning the dryer, air ducts, and area around the dryer daily.

But it’s just as important to know that at higher temperatures, not all moisture meters automatically adjust to provide the most accurate moisture readings. Kett's contact moisture meters have accuracies of plus or minus 0.5% under normal operating conditions, but with certain, lesser moisture meters, high grain drying temperatures can further impact their accuracy, which means it’s important to keep the following points in mind when monitoring grain drying:

- Samples shouldn’t be handled with an uncovered hand, which can add moisture — so too can exposing a sample to air in an open container.

- Take proper procedures for temperature corrections or use a moisture meter that automatically compensates for temperature fluctuations.

Use Laboratory-Grade Instruments Properly

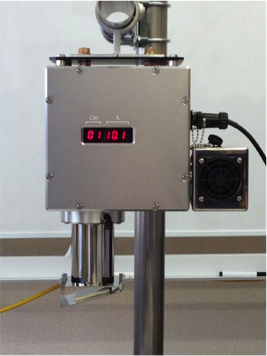

For even higher quality measurements (as good as +/- 0.001%) continuous moisture testing, instruments like Kett’s KB30 Inline Near-Infrared Moisture Meter can take instantaneous, accurate readings of grain in transport at any temperature. It includes automatic temperature compensation, which means users never have to be concerned about correcting moisture readings for various temperatures. Using contact gauges that utilize capacitance, conductance, radio frequency, and similar technologies often provide faulty, if any readings. It’s important to have a full awareness of these kinds of functions to get an accurate reading to limit drying times and help prevent fires.

For other models like the KJT130 portable, KB230 desktop, or the KJT700 online composition meter ambient and product temperature can be almost anything amount...

Having a full understanding of how your high-caliber moisture meter works is essential to the quality and safety of your drying crops, and having a moisture meter that can provide accurate readings at both high and low temperatures is critical. At Kett, our experienced engineers can point you towards field-tested, reliable instruments that offer best-in-class data. To learn more, connect with us today.